- トップ

- 技術情報

- ソリューション

- オートメーションコネクタ

- デモンストレーション一覧

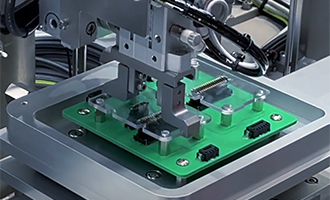

オートメーションコネクタを活用した自動組立デモンストレーション

イリソ電子工業のソリューション「ロボット組立適合コネクタ」を搭載したアプリケーションを、多種多様なロボットで組立し、自動組立の工程を再現したデモンストレーション集です。

様々なロボットメーカー様との実施実績がございますので、具体的事例とともにご紹介させていただきます。

デモンストレーション一覧

IRISO × YAMAHA

ヤマハ発動機様のスカラロボット「YK510XE」とリニアコンベア「LCMR200」を使用し、車載用インバータのパワーモジュールユニットを実装工程から組立工程まで1元化する完全自動組立をイメージしております。

基板組立の自動化で課題とされているダスト防止「キャップ」の取外す工程もスピーディーに対応する事により量産工程に近いデモンストレーションとなっております。

パワー半導体のリードはゲート基板に搭載されているZ-Moveソケット18021Sにて嵌合されており振動共振に対応。

また、基板間に搭載されたコネクタはZ-Move機能を搭載した10120シリーズとフローティング機能を搭載した10109シリーズを同一基板に搭載し、フローティングのメリットである多数個使用においても嵌合が可能。実装誤差や組立位置ずれを吸収し汎用的に使用するスカラロボットとリニアコンベアによる自動組立を実現しております。

基板組立の自動化で課題とされているダスト防止「キャップ」の取外す工程もスピーディーに対応する事により量産工程に近いデモンストレーションとなっております。

パワー半導体のリードはゲート基板に搭載されているZ-Moveソケット18021Sにて嵌合されており振動共振に対応。

また、基板間に搭載されたコネクタはZ-Move機能を搭載した10120シリーズとフローティング機能を搭載した10109シリーズを同一基板に搭載し、フローティングのメリットである多数個使用においても嵌合が可能。実装誤差や組立位置ずれを吸収し汎用的に使用するスカラロボットとリニアコンベアによる自動組立を実現しております。

IRISO × FANUC

FANUC様の協働ロボット「CRXシリーズ」を使用したデモご覧いただけます。弊社の主要なフローティングコネクタを7種実装した3枚の基板に子基板を循環で延々と挿抜を繰り返すシンプルな物ですが、それゆえにそれぞれの特徴をわかりやすく感じていただけると思います。

弊社コネクタの持つフローティング構造によって、力覚・ビジョンセンサ等を使わないロケーションのティーチングのみの作業でも確実でスムースな基板組付け作業を実現しています。またCRXシリーズの協働ロボットならではの動きも浮き彫りになっています。

弊社コネクタの持つフローティング構造によって、力覚・ビジョンセンサ等を使わないロケーションのティーチングのみの作業でも確実でスムースな基板組付け作業を実現しています。またCRXシリーズの協働ロボットならではの動きも浮き彫りになっています。

IRISO × Universal Robots × Kowa Techmake × HIOS

ユニバーサルロボット様の協働型6軸多関節ロボット「URシリーズ」を使用し、箱型モックアップを組み立てるデモンストレーションを行っております。

内部基板にはZ-Moveコネクタ 10120シリーズが搭載されており、フローティング機能が実装誤差を吸収し、ロボット組立を実現させております。

また、I/F部にはUnit-ableコネクタが搭載されており、I/Fコネクタを差し込む際のズレをZ-Move機能が解消します。

Kowa Techmake様の多面ハンドを取り付け、HIOS様のロボット向け電動ドライバーをハンドへ実装することで、基板組立からネジ締めまでの工程を一台のロボットで完全再現しております。

内部基板にはZ-Moveコネクタ 10120シリーズが搭載されており、フローティング機能が実装誤差を吸収し、ロボット組立を実現させております。

また、I/F部にはUnit-ableコネクタが搭載されており、I/Fコネクタを差し込む際のズレをZ-Move機能が解消します。

Kowa Techmake様の多面ハンドを取り付け、HIOS様のロボット向け電動ドライバーをハンドへ実装することで、基板組立からネジ締めまでの工程を一台のロボットで完全再現しております。

IRISO × Mitsubishi × Kowa Techmake × HIOS

三菱電機様の6軸ロボット「RV-FRシリーズ」を3台使用し、小ロット多品種生産品をイメージした箱型モックアップを組み立てるデモンストレーションを行っております。

組み立てだけでなく、ワークの供給作業からネジ締めまでをロボットで再現することで、より完全自動化に近い状態を再現しております。

内部基板の接続には10120シリーズを搭載しており、フローティング機能が実装誤差を吸収しながら接続し、ロボットでの基板嵌合を完成させます。

I/F部にはUnit-ableコネクタを採用し、これまで自動組立に課題のあった小ロット多品種生産品の自動化を可能としています。

材料供給部には協働ロボットを使用することで、安全柵レスを実現し、センサ及びドライバーの出力情報による良否判定と情報のトレーサビリティも実施しております。

組み立てだけでなく、ワークの供給作業からネジ締めまでをロボットで再現することで、より完全自動化に近い状態を再現しております。

内部基板の接続には10120シリーズを搭載しており、フローティング機能が実装誤差を吸収しながら接続し、ロボットでの基板嵌合を完成させます。

I/F部にはUnit-ableコネクタを採用し、これまで自動組立に課題のあった小ロット多品種生産品の自動化を可能としています。

材料供給部には協働ロボットを使用することで、安全柵レスを実現し、センサ及びドライバーの出力情報による良否判定と情報のトレーサビリティも実施しております。

IRISO × ABB × HIOS

ABB様の協働型双腕ロボット「YuMi」で車載カメラモジュールを組み立てるデモンストレーションを行っております。

モジュール内部の基板には10126シリーズが搭載されており、フローティング機能が実装誤差を吸収し、ロボット組立を実現させております。

HIOS様のロボット向け電動ドライバーをYuMiに実装することで、組立からネジ締めまでの工程を完全再現しております。

モジュール内部の基板には10126シリーズが搭載されており、フローティング機能が実装誤差を吸収し、ロボット組立を実現させております。

HIOS様のロボット向け電動ドライバーをYuMiに実装することで、組立からネジ締めまでの工程を完全再現しております。

IRISO × Mitsubishi × Kowa Techmake

三菱電機様の6軸ロボット「RV-FRシリーズ」を2台使用し、PLCを組み立てるデモンストレーションを行っております。

内部基板にはFPC/FFCコネクタ 11501シリーズ、11600シリーズが搭載されており、ノンストップでロボットでのFPCカード挿入を実現しております。

また、メイン基板の接続には10109シリーズが搭載されており、フローティング機能が実装誤差を吸収しながら接続し、ロボットでのセットの組立を完成させます。

Kowa Techmake様の多面ハンドを取り付けることで、ロボット1台につき2つの機能を付与し、組立から通い箱へのワーク整列までを全自動で再現しております。

内部基板にはFPC/FFCコネクタ 11501シリーズ、11600シリーズが搭載されており、ノンストップでロボットでのFPCカード挿入を実現しております。

また、メイン基板の接続には10109シリーズが搭載されており、フローティング機能が実装誤差を吸収しながら接続し、ロボットでのセットの組立を完成させます。

Kowa Techmake様の多面ハンドを取り付けることで、ロボット1台につき2つの機能を付与し、組立から通い箱へのワーク整列までを全自動で再現しております。